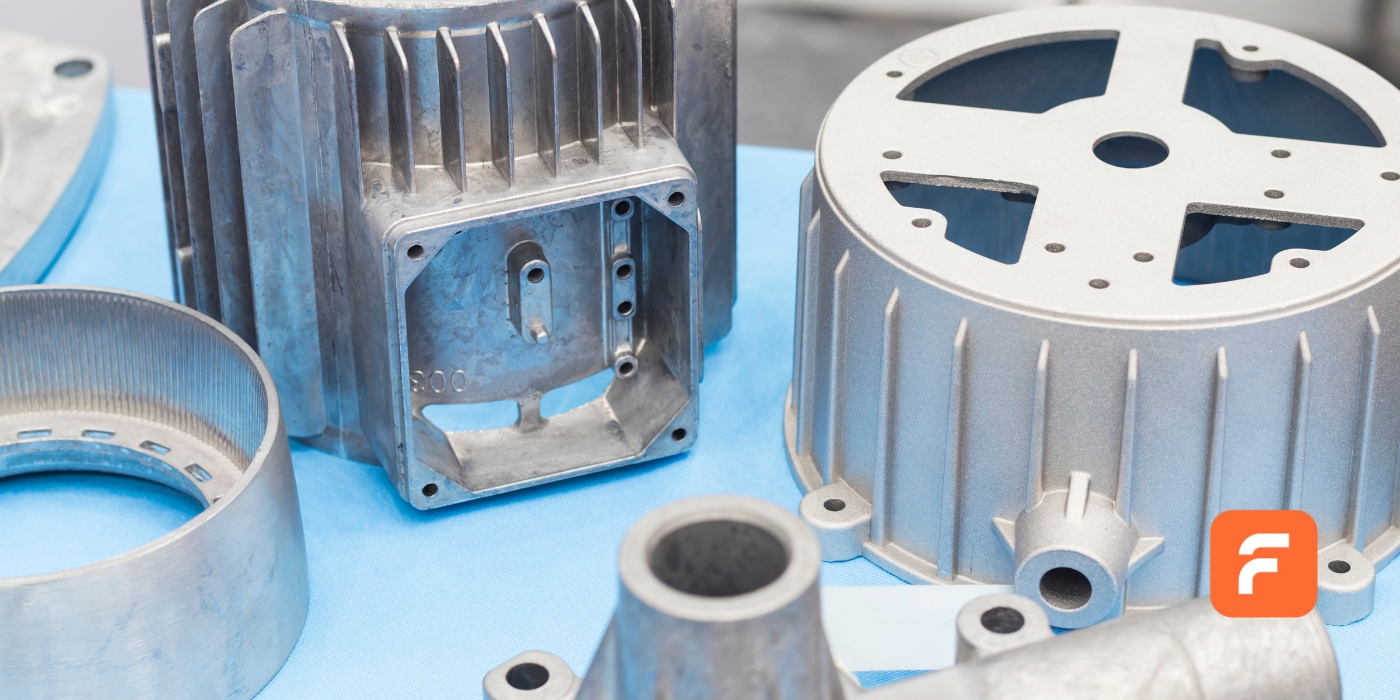

Die casting has become the backbone of modern manufacturing, enabling the production of complex metal parts with exceptional accuracy, strength, and speed. In sectors such as automotive, aerospace, consumer electronics, and heavy machinery, die cast components are vital due to their lightweight, durability, and cost-efficiency.

As global demand for intricate metal components surges, certain manufacturers have positioned themselves as industry leaders, not just for their capacity but also for their innovation, sustainability, and global presence. Here’s a look at the top die casting companies in the world in 2025.

1. GF Casting Solutions AG (Switzerland)

Part of the Georg Fischer Group, GF casting solutions is a frontrunner in high-pressure die casting for aluminum and magnesium components. Headquartered in Switzerland, the company emphasizes lightweight solutions that improve fuel efficiency and reduce emissions. By leveraging AI-driven production and smart automation, GF ensures consistent quality and high-volume capabilities for the automotive and industrial sectors.

2. Dynacast International (USA)

Based in the U.S. and operating under Form Technologies, Dynacast is recognized for its proprietary multi-slide die casting technology. With manufacturing facilities in over 20 countries, Dynacast is a go-to supplier for zinc, aluminum, and magnesium components used in electronics, automotive systems, medical devices, and industrial equipment. Their sustainability initiatives and precision manufacturing set them apart.

3. Nemak S.A.B. de C.V. (Mexico)

Nemak, a Mexico-based multinational, is known for its production of aluminum structural and powertrain components for global automakers. The company is a key player in helping vehicle manufacturers transition to lighter, more energy-efficient models. With multiple production plants worldwide, Nemak integrates environmentally conscious practices and cutting-edge engineering in all their operations.

4. Ryobi Die Casting (Japan)

Ryobi is a major Japanese firm with a strong international footprint. Specializing in aluminum die cast parts for both automotive and electrical applications, Ryobi has remained at the forefront of innovation since its founding in 1943. The company’s R&D efforts focus on improving casting precision, reducing material waste, and boosting part strength.

5. Rheinmetall Automotive AG (Germany)

Rheinmetall, formerly known as Kolbenschmidt Pierburg, has roots going back to the 19th century. The company is highly respected for its aluminum and magnesium die casting operations that supply global automotive OEMs. Their focus on eco-friendly, high-performance vehicle parts aligns with the growing demand for low-emission vehicles.

6. Pace Industries (USA)

Pace Industries offers full-service die casting solutions across North America. With extensive experience in automotive, lighting, aerospace, and medical sectors, the company delivers aluminum, magnesium, and zinc castings with precision engineering. They combine design, prototyping, and production under one roof, streamlining the product development lifecycle.

7. Linamar Corporation (Canada)

Linamar is one of Canada’s largest manufacturing groups, producing highly engineered products for automotive and industrial markets. Their die casting division focuses on aluminum components that meet stringent OEM standards for strength and weight. Linamar continues to invest in smart manufacturing and clean energy solutions.

8. Bocar Group (Mexico)

Established in 1965, Bocar Group provides high-pressure aluminum die casting services primarily to automotive clients. Known for its innovation in lightweight structural parts, the company maintains rigorous quality standards and operates multiple plants across Mexico, Germany, and the U.S.

9. Koch Enterprises – Gibbs Die Casting (USA)

Operating under Koch Enterprises, Gibbs Die Casting has built a solid reputation for delivering precision magnesium and aluminum castings. With a legacy dating back to the 1940s, Gibbs supports major automotive OEMs with a focus on engineering excellence, process stability, and sustainability.

10. Sheffield Forgemasters (UK)

While traditionally known for large-scale forgings, Sheffield Forgemasters also plays a crucial role in the casting industry. They serve the defense, energy, and heavy engineering sectors with complex, large-volume castings. Their emphasis on metallurgical innovation ensures component integrity even under extreme conditions.

Conclusion

The global die casting industry is rapidly evolving, driven by the push for lightweight components, faster production cycles, and eco-conscious manufacturing. The companies listed above represent the pinnacle of this transformation—investing in technology, sustainability, and quality to meet modern manufacturing demands.

Whether you’re sourcing parts for EVs, turbines, or consumer electronics, these top die casting companies are setting the benchmark in 2025.