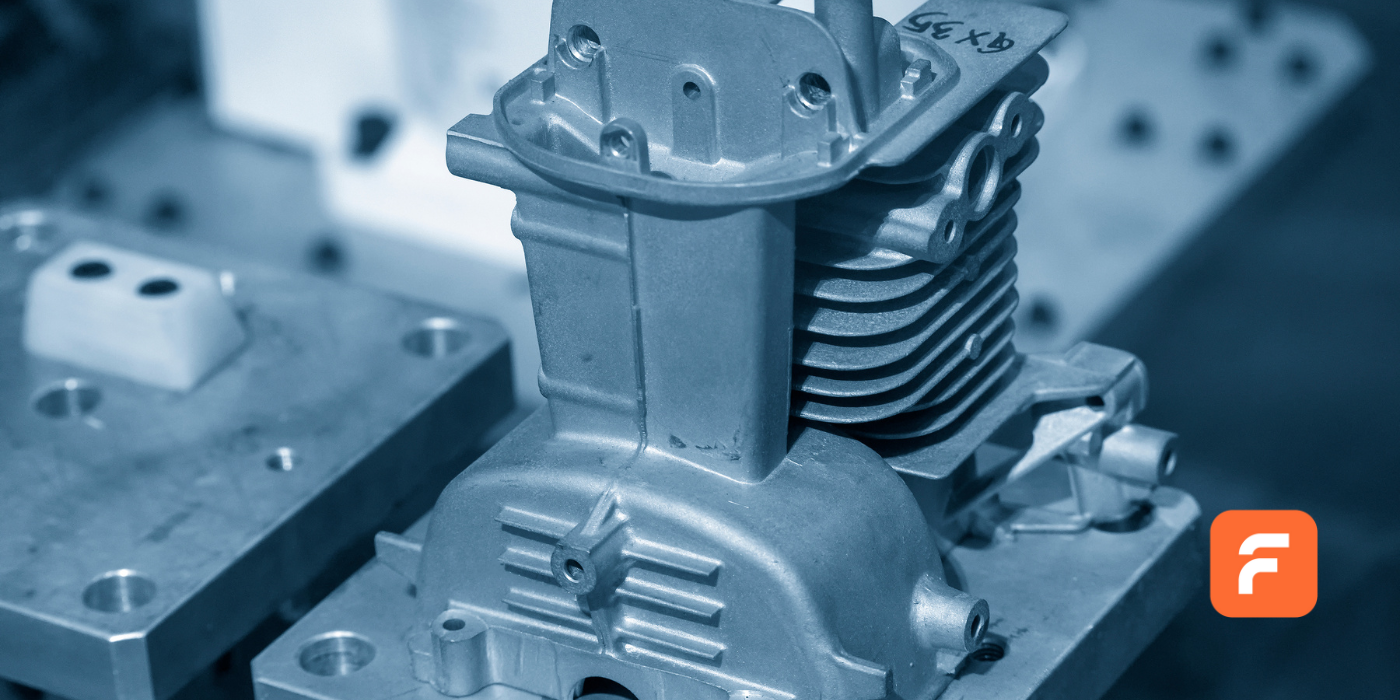

In today’s complex manufacturing landscape, companies sourcing metal components face a key decision: partner with local die casting suppliers or work with global manufacturers. Each option comes with distinct advantages — and potential risks — depending on your priorities.

Below, we compare the benefits of both local and global sourcing for die casting projects, helping you determine the best fit for your operational goals, budget, and product lifecycle.

1. Lead times and logistics

Local suppliers

Working with a local die casting partner offers significantly shorter lead times. Proximity allows for faster delivery, just-in-time inventory, and quicker response to design changes or quality issues.

Local delivery also reduces your dependence on international freight, port delays, and customs clearance.

Global suppliers

Global die casting suppliers, especially in regions like Asia, may offer competitive pricing — but often at the cost of longer lead times and complex shipping logistics. Expect extended timelines for tooling, prototyping, and full-scale production.

2. Cost efficiency

Global suppliers

Offshore suppliers often offer lower unit costs, particularly for high-volume orders. Labor and operational expenses in countries like China, India, and Vietnam are typically much lower, which can lead to significant cost savings for large-scale projects.

Local suppliers

While domestic suppliers may have higher per-unit costs, those are sometimes offset by reduced shipping fees, quicker turnaround, fewer errors, and lower risk of rework or delays — especially for low-to-medium volume production.

3. Communication and collaboration

Local suppliers

Time zone alignment and language compatibility make working with local manufacturers easier. Real-time collaboration, on-site visits, and faster feedback cycles help speed up design iterations and decision-making.

Global suppliers

Language barriers and time zone gaps can make communication more difficult. Video calls and emails may suffice for mature projects but may hinder rapid changes during product development.

4. Quality assurance and oversight

Local suppliers

With a domestic die casting supplier, quality control is easier to audit. You can visit facilities, participate in first-article inspections, and ensure compliance with regional standards like ISO 9001 or IATF 16949.

There’s greater transparency and accountability throughout the production cycle.

Global suppliers

While many international suppliers maintain high quality standards, oversight is harder to manage without a local representative or third-party inspection agency. Travel restrictions or geopolitical issues may further complicate site audits.

5. Supply chain risk

Global suppliers

Global supply chains face challenges like port congestion, rising freight costs, tariffs, and political instability. Events such as COVID-19 or conflicts in major trade regions have exposed the risks of over-reliance on offshore manufacturing.

Local suppliers

Local die casting suppliers offer more resilience, especially for mission-critical or time-sensitive components. Shorter supply chains reduce exposure to global disruptions and allow for faster recovery in emergencies.

6. Sustainability and ESG goals

Local suppliers

Sourcing locally supports sustainability goals by lowering your carbon footprint (less transportation), encouraging regional economic growth, and simplifying regulatory compliance. It also aligns with growing ESG and reshoring trends.

Global suppliers

Global sourcing can still be sustainable — but it requires strict oversight of materials, labor practices, and emissions. Without transparency, your brand may carry hidden ESG risks.

Conclusion

There’s no one-size-fits-all solution when it comes to sourcing die castings.

Local suppliers offer speed, flexibility, and control — ideal for complex parts, iterative development, or mission-critical timelines.

Global suppliers provide cost advantages — best suited for mature designs and high-volume production with predictable demand. The right choice depends on your priorities: cost vs control, volume vs agility, and risk tolerance vs convenience.